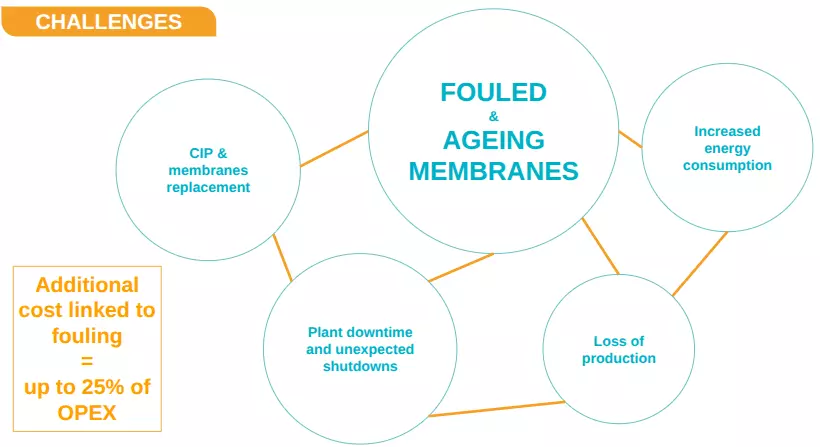

25% of an RO plant's operational expenditure (OPEX) can be attributed to membrane fouling alone, driving up costs and risking unplanned shutdowns. For South Korea's water treatment and desalination sector, where reliability and cost control are paramount, the challenge of invisible membrane fouling and unpredictable maintenance schedules is a daily reality. Technical directors, operations managers, and maintenance teams face mounting pressure to optimize performance, extend asset life, and meet sustainability targets, all while keeping costs in check.

Hubgrade for Water Operations (HWO) introduces a new paradigm: Smart Membrane, an AI-powered solution that leverages real-time data and machine learning to predict, optimize, and benchmark every aspect of reverse osmosis (RO) membrane maintenance. This article explores how Smart Membrane is reshaping water operations in South Korea, providing actionable insights for municipal and industrial stakeholders.

Key takeaways for water sector leaders

- Fouling and aging membranes can drive up to 25% of RO plant OPEX, with early replacement and energy costs as major contributors.

- Traditional maintenance relies on fixed schedules or reactive interventions, often missing the true state of membrane health.

- Smart Membrane uses real-time normalized fouling indicators and machine learning to forecast optimal cleaning and replacement times.

- Predictive maintenance reduces downtime, extends membrane life, and enables evidence-based decision-making for operators and managers.

- Case studies show significant time savings, improved plant uptime, and direct cost reductions for both municipal and industrial facilities.

For South Korean water professionals, understanding and applying AI-driven membrane management is key to achieving operational excellence and sustainability.

The hidden cost of membrane fouling: challenges for water operations

Reverse osmosis plants are the backbone of South Korea’s drinking water, wastewater, and desalination infrastructure. Yet, beneath the surface, membrane fouling and aging silently erode performance, driving up costs and threatening reliability. Operators often struggle with:

- Unplanned shutdowns and production losses: When fouling goes undetected, plants risk unexpected downtime, lost output, and contractual penalties. For example, a single train offline for 24 hours at a large desalination plant can result in over 12,000 m³ of lost production, translating to thousands of dollars per day.

- Inefficient maintenance schedules: Fixed cleaning intervals or reactive interventions may lead to unnecessary Clean-in-Place (CIP) events, wasted chemicals, and premature membrane replacement. This not only increases direct costs but also disrupts operations.

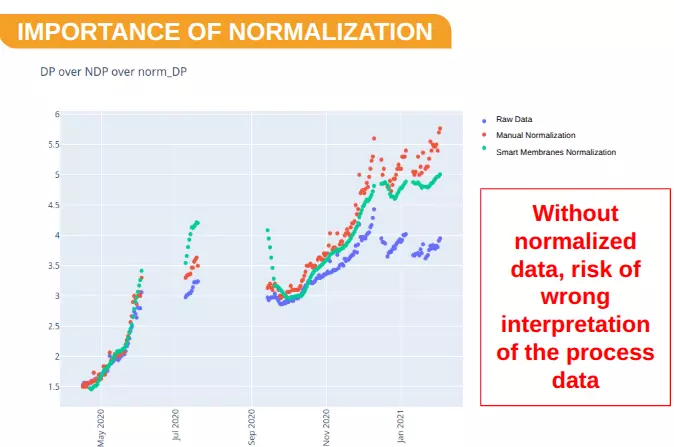

- Complex data interpretation: Raw operational data is influenced by external factors like temperature, feed flow, and conductivity, making it difficult to assess the true state of membrane fouling. Manual normalization is time-consuming and prone to error.

- Resource constraints: With plants often running near full capacity, stopping a train for maintenance is a major operational challenge. Maintenance managers and process engineers need reliable decision support tools to optimize schedules and minimize downtime.

“Our challenge today is to keep running the plant with the same capacity and quality.”

The consequences are clear: up to 25% of OPEX can be linked to fouling, with early membrane replacement and increased energy consumption as the main drivers. For South Korean facilities, where energy costs and water quality standards are high, the stakes are even greater.

How Smart Membrane leverages AI and machine learning for predictive maintenance

Smart Membrane, part of the Hubgrade for Water Operations suite, addresses these challenges by combining real-time data analytics, normalization algorithms, and predictive modeling. Here’s how it works:

Real-time normalized fouling indicators

Traditional monitoring relies on raw data, which can be misleading due to fluctuating operational conditions like temperature, feed flow, and conductivity. Smart Membrane uses a Generalized Additive Model (GAM) to normalize key fouling indicators, such as differential pressure, permeate conductivity, and specific flux, removing the influence of these external factors.

Why GAM makes the difference: Unlike simpler linear models or rigid, predetermined formulas, GAMs capture complex, non-linear relationships between operational parameters and membrane performance. By learning these intricate patterns directly from your plant's unique data, Smart Membrane accurately isolates the true impact of fouling and aging, even in highly variable operating environments. This provides a clearer, more reliable picture of membrane health than traditional methods.

Key advantages:

- No supplier formulas required: The normalization algorithm is trained on plant-specific data, especially from new or clean membranes, ensuring tailored insights.

- Holistic visibility: Operators can access real-time normalized data and download graphs for easy reporting and analysis.

"Thanks to SM, it is possible to identify any issue sooner than with the monthly extraction, and be more proactive in planning the corresponding corrective action. I used to never look at the normalization files, now I can check it in two clicks." - Maintenance Manager

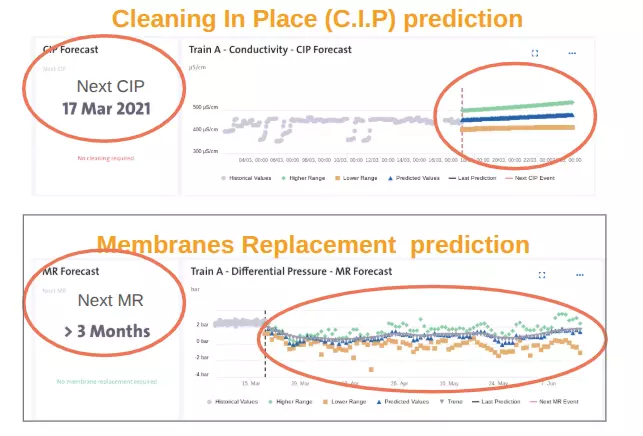

Predictive CIP and membrane replacement forecasting

Machine learning models analyze historical and current data to forecast the optimal timing for CIP and membrane replacement:

- CIP optimization: The system predicts fouling trends over the next week, recommending cleaning only when necessary. This delays non-essential CIPs, reduces chemical use, and avoids unplanned shutdowns.

- Membrane replacement prediction: Forecasts replacement needs up to three months in advance, supporting proactive stock management and maintenance planning.

- User-adjustable thresholds: Operators can set custom triggers for key parameters, tailoring recommendations to plant-specific requirements.

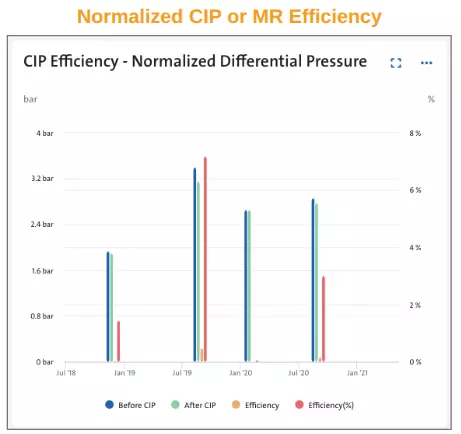

Predictive maintenance mapping and benchmarking

Smart Membrane provides a dashboard overview of all RO trains, highlighting which units

require attention. Maintenance events are logged directly in the interface, enabling:

- Benchmarking of CIP and replacement efficiency: Compare different cleaning recipes and strategies to identify the most effective approach.

- Production cycle analysis: Automatically detect and compare performance across production cycles, supporting continuous improvement.

- Maintenance history integration: Reliable event logging ensures accurate data for future analysis and decision-making.

Beyond the Basics: What Makes Smart Membrane Stand Out?

Adaptive, AI-Driven Normalization (No Black Box Formulas)

Unlike solutions that rely on generic, fixed formulas from membrane suppliers or manual, error-prone calculations, Smart Membrane's Generalized Additive Model (GAM) learns the unique operational dynamics of your specific plant. It precisely accounts for external variables in real-time, providing an unbiased, accurate assessment of membrane health without requiring you to input or adapt complex, proprietary equations.

True Predictive Intelligence, Not Just Alerts

We move beyond simple thresholds or fixed-interval maintenance. Our machine learning models don't just tell you what is happening, but when critical interventions like CIP or membrane replacement will be optimally needed. This enables proactive planning, allowing you to schedule maintenance precisely when it's most effective, rather than reacting to failures.

Holistic Operational Insight & Benchmarking

Smart Membrane integrates seamlessly with your plant's data, offering a comprehensive, real-time view of all RO trains. It provides robust benchmarking capabilities for CIP and replacement efficiency, alongside a detailed event logging system. This creates a single source of truth for maintenance planning and continuous performance optimization, a level of integrated insight often missing in disparate monitoring tools.

Quantified benefits: case study and real-world results

LG Chemical & Lotte Chemical

Challenge:

The facility needed to automatically upload reverse osmosis water (RO Water) operation data and identify changes in operation status with AI to help determine when to implement CIP (Clean-In-Place) and when to replace RO membranes. The plant required optimization of maintenance schedules to reduce operational costs and extend membrane life while maintaining production capacity and quality.

Solution:

Smart Membrane technology was installed in June 2024 with an expected operational period through October 2025. The AI-powered solution enabled:

- Automatic monitoring and analysis of RO water operation data

- Real-time identification of optimal CIP timing and membrane replacement needs

- Predictive maintenance scheduling based on actual membrane condition rather than fixed intervals

- Data-driven decision support for maintenance teams

Results:

The implementation delivered significant operational and financial benefits:

- 10% reduction in drug usage costs through CIP optimization, saving €9,400 per year

- 20% savings in membrane replacement timing, saving €24,000 per year

- Extended membrane lifespan through optimized maintenance scheduling

- Improved operational efficiency and reduced unplanned downtime

- Total annual savings of approximately €33,400 from combined drug and membrane cost reductions

The facility successfully transitioned from reactive, schedule-based maintenance to predictive, condition-based maintenance, demonstrating the value of AI-powered membrane management in industrial water treatment applications.

Funding, incentives, and regulatory context in South Korea

South Korea’s water sector is supported by several funding and regulatory initiatives aimed at promoting digital transformation and sustainability:

- K-water Smart Water Management Program: Provides grants and technical support for digital water operations, including AI-powered solutions for municipal and industrial facilities.

- Ministry of Environment Green New Deal: Offers incentives for energy-efficient and resource-optimized water treatment technologies, with a focus on reducing OPEX and carbon footprint.

- Regulation on Drinking Water Quality and Plant Reliability: Mandates strict standards for water quality and operational uptime, encouraging adoption of predictive maintenance and advanced analytics.

These programs align with the goals of Smart Membrane, supporting investment in AI-driven water treatment optimization.

Action steps for South Korean water professionals

Adopting Smart Membrane is a strategic move for technical directors, operations managers, and maintenance teams seeking to:

- Switch from preventive to predictive maintenance: Move beyond fixed schedules and reactive interventions to data-driven, proactive management.

- Optimize OPEX and resource use: Reduce operator time, chemical consumption, and premature membrane replacement.

- Increase plant uptime and reliability: Minimize unplanned shutdowns and production losses, meeting contractual and regulatory requirements.

- Extend membrane lifespan: Benchmark and refine cleaning strategies to maximize asset life.

- Enhance decision-making: Access real-time insights and historical benchmarks for continuous improvement.

To get started, facilities should prepare key operational data, such as chemical consumption per CIP, CIP frequency, total number of membranes, and replacement rates, to enable tailored Smart Membrane deployment.

Take the next step towards smarter, safer, and more sustainable water operations