Do you know exactly how efficiently your industrial cooling tower is running today?

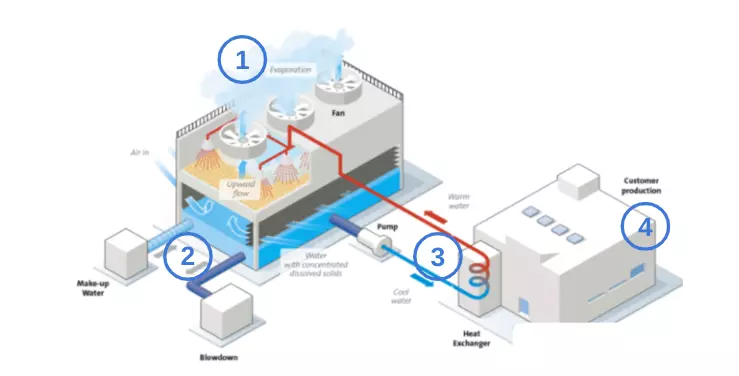

For many manufacturing plants in South Korea, cooling tower water treatment systems are critical for stable production in oil refineries, petrochemicals, metal, food processing, and data centers. While these industrial cooling towers ensure process temperature control and protect equipment, their actual performance often goes unmeasured or under-optimized. In the age of digital transformation, this lack of smart monitoring is a missed opportunity.

This lack of visibility can hide costly inefficiencies: excessive water consumption, chemical waste, high energy costs, and unplanned downtime. In today’s competitive industrial environment, where utility costs are rising and environmental regulations are tightening, digital water management systems and real-time monitoring platforms are no longer optional, they are essential for business success.

By implementing advanced cooling tower performance solutions through digital transformation, Korean manufacturers can significantly reduce operating costs, improve system reliability, and meet ambitious ESG targets. Our Hubgrade digital platform has helped clients achieve up to 16% improvement in cooling efficiency, 17% reduction in chemical costs, and 25% water savings.

Industrial Cooling Tower Management Models: Assessing Your Current Performance Level

Understanding your current cooling tower performance level is the first step toward optimization.

Below are the four main cooling tower water treatment system management models used across Korean manufacturing sites, each impacting operational efficiency, costs, and ESG performance differently.

Choosing the right cooling tower management model depends on your specific industrial needs, water treatment requirements, and long-term performance goals.

Maximizing Industrial Cooling Tower Performance: Benefits and ROI

Without smart water treatment systems and real-time performance monitoring, your industrial cooling tower is likely operating below optimal efficiency. In Korean manufacturing, such inefficiencies directly impact operational costs, regulatory compliance, and sustainability targets.

Key Performance Challenges in Under-Optimized Cooling Systems

- Lack of smart monitoring and automated controls

- Excessive water consumption from uncontrolled blowdown or outdated purge cycles

- Chemical waste due to manual or inaccurate dosing

- High energy costs from inefficient pump and fan operation

- Missed opportunities for industrial water treatment optimization

- Unplanned downtime disrupting production continuity

- Increased ESG risks from exceeding water discharge or thermal limits

- No real-time visibility into system performance

- Inability to predict and prevent equipment failures

- Lack of data-driven decision making capabilities

- Limited integration with other plant systems

Digital Solutions and Benefits: Transform Your Cooling Tower Performance

What difference can digital solutions make for your cooling system? Our data tells the story: measurable before-and-after improvements in efficiency, costs and sustainability.

1. Optimization of Cooling Tower system (Cooling Efficiency)

- Before:

Optimal Cooling Water temperature and energy consumption through real-time monitoring of cooling tower wet bulb temperature. - After:

16% improvement in cooling efficiency

8% reduction in energy consumption

Real-time optimization via digital monitoring

2. Intelligent Chemical Management

- Before:

Manual chemical dosing

Excessive chemical use - After:

17% reduction in chemical costs

15% less corrosion inhibitor usage

20% reduction in scale inhibitor consumption

Automated dosing with real-time monitoring

3. Power Consumption Optimization

- Before:

Unmonitored energy usage

Inefficient operations - After:

14% improvement in pump efficiency

15% overall energy savings

Continuous power monitoring and control

4. Smart Blowdown Management

- Before:

Manual blowdown control

Water waste - After:

25% reduction in blowdown volume

25% savings in makeup water

Automated quality control

5. AI-Powered Predictive Maintenance

- Before:

Reactive maintenance

Unexpected downtime - After:

Continuous operation

Early problem detection

Extended equipment life

Reduced maintenance costs

These measurable improvements are achieved through our Hubgrade digital platform, enabling real-time monitoring and optimization across all systems.

Regulatory Context for Korean Manufacturing

Under the Water Environment Conservation Act, cooling tower blowdown is classified as industrial wastewater and must meet strict discharge quality standards. Thermal discharge regulations require water to be cooled before release, while public health guidelines mandate Legionella prevention through regular cleaning, drift eliminators, and approved biocides.

Failing to optimize your cooling tower can result in:

- Increased operational costs.

- Risk of non-compliance and fines.

- Missed ESG and sustainability commitments.

Bottom line: Implementing smart industrial cooling tower performance solutions is no longer optional, it’s essential for achieving operational excellence, regulatory compliance, and sustainable growth in South Korea’s manufacturing sector.

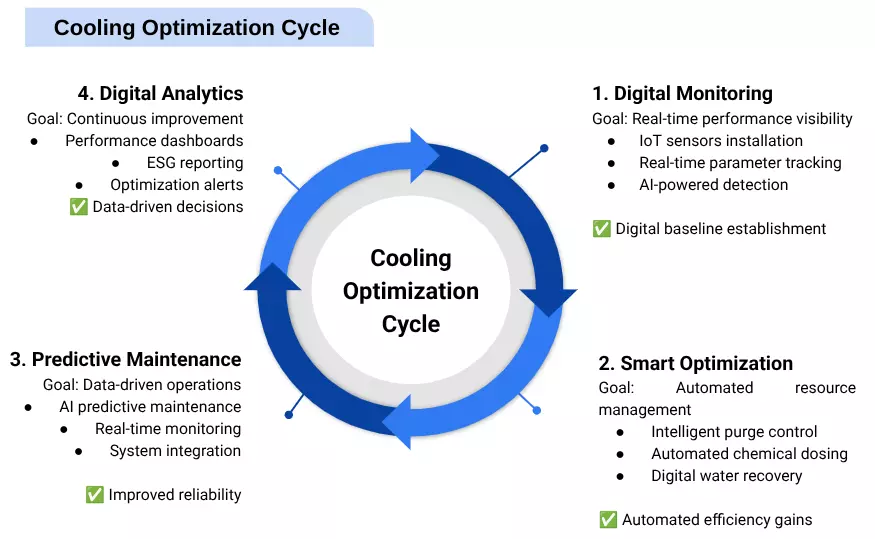

4-Step Smart Water Treatment System: Optimizing Industrial Cooling Tower Performance

Our comprehensive industrial cooling tower performance approach combines smart digital solutions with continuous monitoring through the Hubgrade platform. This proven 4-step optimization cycle delivers measurable efficiency gains for Korean manufacturing facilities.

Each step of our digital optimization process is powered by advanced monitoring and control:

- Real-time performance monitoring and smart analytics

- AI-driven optimization of water treatment systems

- Predictive maintenance and automated operations

- Continuous improvement through data-driven insights

This digital approach transforms cooling towers into smart, connected assets that deliver measurable efficiency gains and sustainable performance.

Regulatory Requirements for Industrial Cooling Tower Performance in Korea

For Korean manufacturing facilities, smart water treatment systems and cooling tower performance optimization are essential for meeting strict environmental and public health regulations.

Water Treatment and Discharge Compliance (Water Environment Conservation Act)

- Cooling tower blowdown classified as industrial wastewater

- Strict quality standards for discharge

- Continuous monitoring required

- Exemptions possible with proven compliance record

Health and Safety Standards

- Mandatory Legionella prevention program

- Required drift eliminator installation

- Approved biocide treatment protocols

- Regular cleaning and maintenance schedule

Performance Monitoring Requirements

- Real-time data collection

- Regular compliance reporting

- Quality parameter tracking

- Documentation requirements

Thermal Performance Requirements

- Maximum temperature limits for water discharge

- Closed-loop systems increasingly mandatory

- Continuous temperature monitoring needed

- Impact on aquatic ecosystem protection

Environmental Impact Regulations

- Noise level compliance requirements

- Plume control in sensitive areas

- Best Available Techniques (BAT) implementation

- ESG reporting obligations

Meeting these regulations requires advanced cooling tower performance monitoring and smart water treatment systems. Our solutions help Korean manufacturers achieve both compliance and operational excellence while supporting ESG goals.

From Compliance to Performance Optimization

In South Korea’s competitive manufacturing sector, industrial cooling tower performance has evolved beyond routine maintenance, it is now a strategic driver of operational efficiency and sustainability. With rising utility costs, stricter environmental regulations, and growing ESG expectations, smart water treatment systems are becoming essential.

By implementing advanced cooling tower performance solutions, Korean manufacturers can achieve:

- Up to 25% reduction in water consumption

- 17% decrease in chemical costs

- 15% reduction in energy usage

- Extended equipment lifespan through AI-powered predictive maintenance

- Real-time performance optimization via the Hubgrade platform

- Full regulatory compliance and measurable ESG achievements

Optimizing your industrial cooling tower performance isn’t just about meeting standards, it’s about gaining a competitive edge through smart digital solutions and data-driven operations.

Want to go further?