Is your industrial site prepared for Korea’s tougher wastewater rules in 2025?

Regulatory pressure is rising. K-eco continues to strengthen enforcement, with hundreds of administrative actions annually across industrial sectors. With new discharge limits, real-time monitoring requirements, and stricter audits taking effect, the cost of inaction is growing.

This article breaks down what is changing, what is expected from your site, and how leading companies are turning compliance into a performance driver.

Why Wastewater Compliance Matters More Than Ever in 2025

In 2025, wastewater compliance in South Korea is no longer just a regulatory formality. It has become a strategic imperative for industrial sites that want to operate responsibly, avoid financial penalties, and maintain their position in global value chains.

The Ministry of Environment (MOE) and Korea Environment Corporation (K-eco) are strengthening their oversight of industrial wastewater discharge. Audits are more frequent, standards are stricter, and digital monitoring systems like TMS (Tele-Monitoring System) are now mandatory for many facilities.

Non-compliance can lead to heavy consequences. Beyond financial penalties, companies risk public disclosure, suspension of operating permits, and damage to their ESG ratings. For businesses exporting to ESG-sensitive markets or applying for green financing, failing a wastewater audit can block access to investment and partnerships.

More than ever, industrial players must treat environmental compliance as a key part of their operational and sustainability strategy.

Key Wastewater Discharge Regulations in Korea: What Has Changed

South Korea’s industrial wastewater regulations are defined by the Water Environment Conservation Act, the country’s main legal framework for protecting surface water quality. This law is enforced by the Ministry of Environment (MOE) and implemented in the field by Korea Environment Corporation (K-eco).

In recent years, regulations have been tightened to address growing environmental concerns, especially around river basin health and ESG accountability.

Discharge Permit System: Who Is Concerned?

Any industrial facility discharging wastewater must obtain an official discharge permit from the local environmental authority. This permit outlines:

- Maximum volume of effluent allowed

- Specific pollutant concentration limits

- Required treatment technologies

- Monitoring and reporting obligations

Facilities are classified by risk level, from Category 1 (high-pollution potential) to Category 4 (low impact). High-risk sites, such as those in the chemical or semiconductor sectors, are subject to more stringent controls and inspection frequencies.

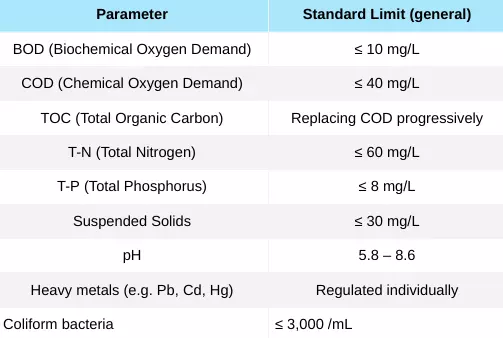

Updated Discharge Standards: Focus on Tighter Limits

Over the past few years, pollutant thresholds have been reduced and the number of regulated substances has increased. One major evolution is the gradual replacement of COD (Chemical Oxygen Demand) by TOC (Total Organic Carbon) as a primary indicator of organic pollution.

Here are the most common parameters currently regulated:

These limits may be stricter for discharges into protected zones, including drinking water areas and TMDL-regulated basins.

Sensitive Zones and TMDL Policy

The government has designated specific regions as Total Maximum Daily Load (TMDL) zones, where the total pollutant load allowed into a river basin is capped.

This applies especially to:

- The Han River basin, which supplies water to over 25 million people

- The Nakdong and Geum River basins, in areas with high industrial concentration

- Seoul Metropolitan Area sites connected to major public wastewater treatment centers (Jungnang, Tancheon, etc.)

Facilities located in these zones must often meet tighter limits than the national baseline and may be subject to additional audits or data submission requirements.

Real-Time Monitoring and TMS: What’s Required from Industrial Sites

To strengthen oversight and prevent environmental accidents, South Korea has made real-time wastewater monitoring a core requirement for many industrial sites. This is managed through the TMS (Tele-Monitoring System), a digital platform operated by K-eco under the supervision of the Ministry of Environment.

Is TMS Mandatory for Your Facility?

The TMS is mandatory for:

- Sites with high wastewater discharge volumes

- Facilities located in environmentally sensitive zones such as TMDL river basins or drinking water protection areas

- High-risk industries like semiconductors, chemicals, electronics, or metals

Once designated, a facility must install certified sensors and data loggers to continuously monitor its wastewater discharge quality and quantity.

What Data Must Be Transmitted?

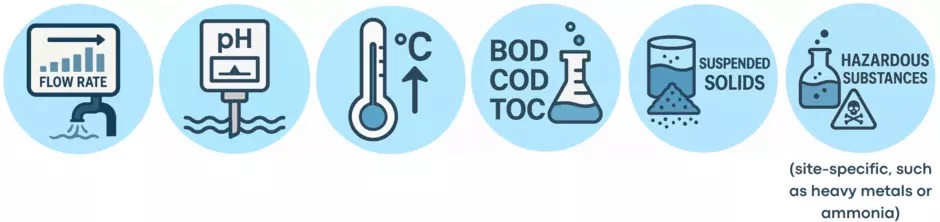

Key parameters measured and reported include:

Data is transmitted to K-eco’s central system in real time. If abnormal values are detected, the system can automatically trigger alerts to both the site operator and environmental authorities.

How to Prepare for a K-eco Inspection

K-eco conducts both scheduled and unannounced inspections of facilities connected to TMS. To stay ready:

- Regularly check sensor calibration and data transmission status

- Keep a clean, updated record of your discharge logs and system maintenance

- Set up internal alert systems to react immediately to abnormal readings

- Ensure staff are trained in compliance procedures and emergency protocols

Being proactive not only reduces the risk of penalties but also shows clear commitment to responsible environmental management.

Sector-Specific Compliance Challenges

While all industrial sites in Korea must meet national wastewater standards, certain sectors face additional challenges due to the nature of their effluents. These challenges often require more advanced treatment systems, stricter monitoring protocols, and tailored compliance strategies.

Semiconductor and Electronics

This sector generates large volumes of acidic and alkaline wastewater, often containing:

- Fluoride compounds

- Ammonia and ammonium

- Heavy metals such as copper or chromium

These substances require a multi-step treatment process, typically including neutralization, precipitation, filtration, and membrane systems.

Compliance tips:

- Regularly monitor pH and fluoride concentration

- Ensure compatibility between treatment chemicals and discharge limits

- Track chemical usage and recovery rates to optimize efficiency

Chemical Industry

Chemical manufacturers often discharge highly variable and complex effluents. These may include:

- Volatile organic compounds (VOCs)

- Toxic substances

- Residual solvents and dyes

Facilities in this sector are frequently classified as high-risk by K-eco and are often subject to stricter permit conditions and audit frequencies.

Compliance tips:

- Install advanced pre-treatment units and chemical dosing control

- Maintain an up-to-date inventory of all regulated substances

- Train staff on hazardous waste handling and emergency scenarios

Food and Pharmaceutical Industries

These facilities typically release wastewater with:

- High biochemical oxygen demand (BOD)

- High organic and nutrient loads (e.g. nitrogen, phosphorus)

- Potential pathogenic contamination in pharmaceutical effluents

Biological treatment is essential, often followed by nutrient removal systems to meet local discharge standards.

Compliance tips:

- Monitor and adjust biological process performance regularly

- Ensure nutrient removal steps meet T-N and T-P limits

- For pharma sites, follow additional guidelines related to emerging contaminants

Turning Compliance Into Competitive Advantage

For many industrial sites, wastewater regulations are still seen as a constraint. But in 2025, forward-thinking companies are reframing compliance as a driver of operational performance and ESG leadership.

Facilities with reliable, traceable monitoring systems are better equipped for ESG audits, sustainability ratings, and green financing applications. Demonstrating compliance not only reduces the risk of sanctions, it builds trust with regulators, investors, and supply chain partners.

At the operational level, well-managed wastewater systems improve resource efficiency. They can open the door to water reuse, help lower utility costs, and reduce environmental risks associated with accidental discharge or system failure.

Some industrial sites in Korea have partnered with service providers like Veolia to upgrade their treatment systems and improve their real-time monitoring capacity, ensuring both compliance and long-term performance. These partnerships can also support process optimization, reduce sludge generation, and recover valuable by-products.

Ultimately, compliance is no longer just about avoiding penalties. It is about building a resilient, responsible, and resource-efficient industrial model.

Stay Ahead, Not Just Compliant

With tighter wastewater regulations, enhanced monitoring systems, and growing ESG scrutiny, simply meeting the minimum requirements is no longer enough. Industrial sites in Korea must move from reactive compliance to proactive environmental management.

Waiting for an audit or a non-compliance notice can put operations, reputation, and business partnerships at risk. The best time to evaluate your wastewater performance is before it becomes a problem.

Start by reviewing your current discharge permit, monitoring systems, and treatment capacity. Identify gaps, anticipate future changes, and explore opportunities for improvement.