Hidden Costs of Industry: Increased Costs Due to Fouling in Facility

In a domestic economic structure that relies on imports for over 90% of its energy resources, the energy efficiency of industrial facilities goes beyond simple cost savings and is a crucial indicator directly linked to national competitiveness. Especially in industries with high energy consumption such as petrochemicals, steel, and semiconductors, a huge amount of heat energy is consumed and released, and heat exchangers and cooling towers play a key role in this process. However, the most fatal and chronic factor that reduces the performance of these heat exchange facilities is ‘fouling’. Fouling refers to a phenomenon in which unwanted substances such as dust, scale, microorganisms, and sediments are deposited inside or on the surface of equipment such as pipes and heat exchangers, increasing heat transfer resistance and obstructing fluid flow.

(Cross-section of severe fouling formed inside pipes, heat exchangers, and boilers)

The answer to uncovering and reducing hidden costs in industry while simultaneously achieving carbon neutrality goals lies in Veolia's "Hubgrade Smart Fouling" solution, which combines AI-based machine learning and predictive control technology.

Smart Fouling is one of Veolia's unique digital services provided through Hubgrade, a data analytics, supervision, optimization and predictive systems for water, waste, energy and other environmental resources.

Using the power of data and the most advanced AI technologies trained with our worldwide operational expertise, we tailor solutions for your specific ecological transformation journey, whether it’s decarbonization, depollution, or resource saving and regeneration.

Key takeaways:

- Efficient operation of equipment by predicting the effective removal cycle of fouling

- 20% annual operating cost reduction

- No need to replace existing systems

- Applicable to facilities in various industries

Concerns facing Korean industry

Domestic industrial sites exhibit complex fouling patterns due to the distinct climate of the four seasons and the use of various water sources (river water, industrial water, seawater, etc.). These phenomena occur singly or in combination in major domestic industrial complexes, reducing facility efficiency.

- Types of fouling:

- Particulate fouling: A phenomenon in which suspended matter settles on a surface.

- Crystalline fouling (Scaling): A phenomenon in which inorganic salts such as calcium and magnesium become supersaturated and precipitate (scale).

- Biofouling: A phenomenon in which microorganisms form a biofilm and attach themselves, causing significant pressure drop, especially in reverse osmosis (RO) membranes and cooling towers.

- Energy loss mechanism: The fouling layer acts as an insulator, hindering heat transfer (heat exchanger) or blocks the flow of fluid, increasing the load on the pump (RO membrane). As electricity costs continue to rise in Korea, the additional electricity consumption due to fouling (Scope 2 emissions) is having a devastating impact on corporate profitability .

The status and risks of fouling by major industry are as follows.

Smart solutions through data analysis are essential to prevent these risks in advance and manage them efficiently.

Preemptive predictive solutions using AI digital technology

Veolia's optimal AI technology and water treatment/energy management technologies predict fouling in real time and provide preventative solutions rather than reactive ones.

1. Predictive Analytics and Process Control

By analyzing past data through machine learning, we predict future situations based on various factors that cause fouling. Optimized operation is possible by suggesting the most efficient operation strategy through simulation using a predictive model and efficiently suggesting the timing of fouling removal.

2. 20% annual reduction in operating costs

Beyond improving maintenance efficiency, it also reduces overall operating costs by improving equipment cooling efficiency, reducing energy consumption, reducing water usage, and eliminating unnecessary fouling.

3. Increased facility efficiency

By effectively eliminating fouling, a risk in the process, you can increase the durability and performance of your equipment.

4. Applicable to facilities in various industries

This model can be applied to core processes in various industries where fouling occurs, and it supports customers to demonstrate their capabilities in their respective industries through efficient fouling management.

5. No Need to Replace Existing Systems

This service works simply by connecting operational data from existing systems to Hubgrade, eliminating the need to replace current infrastructure.

Major Domestic Reference Cases

Case #1: Kleannara

Kleannara, a paper industry client located in Cheongju, provides Veolia with SRF boiler operation and maintenance, energy management through steam supply, and water and wastewater treatment services.

*Solution: By utilizing Hubgrade's "Smart Fouling" solution, an AI digital solution from Veolia, we monitor and analyze the phenomenon of heat transfer interference caused by foreign substances (fouling) occurring in the water tubes of SRF boilers. Based on this, we predict and improve the optimal fouling removal cycle to enhance heat transfer efficiency.

*Expected effect

- Efficient operation of the facility through optimization of the fouling cleaning cycle.

- Reduce unnecessary costs by operating efficient facilities

- Increasing steam production through energy efficiency optimization

We actively support our clients' ESG management by providing optimized operations and maintenance through smart fouling solutions that integrate AI and reduce unnecessary resource use.

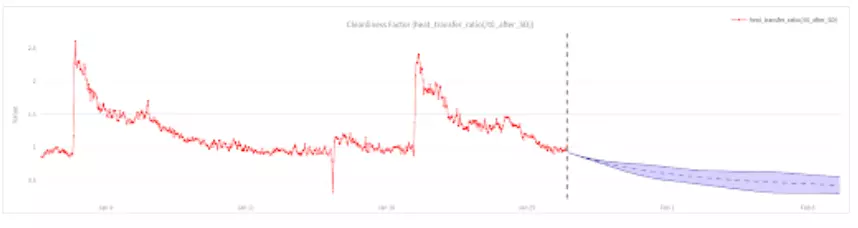

(Smart Fouling Solution: Predicts the timing for fouling removal by monitoring and analyzing thermal conductivity trends based on various parameter values.)

Case #2: Uniken - Hazardous Waste Facility

Uniken is a hazardous waste treatment facility in Ulsan, including two incinerators (with annual capacities of 13,000 and 35,000 tons), liquid designated waste treatment (12,000 tons/year), and industrial wastewater treatment (153,000 tons/year).

*Solution: To effectively remove periodic fouling in the piping of a designated waste incinerator, predict and apply the fouling removal cycle by monitoring boiler heat transfer efficiency trends based on existing operating data. Maximization of steam production by introducing a fouling removal method that enables uninterrupted operation.

*Expected effect

- Increased heat transfer efficiency through optimization of fouling cleaning cycles

- Providing intuitive information through data dashboarding

- Reduce unnecessary costs by operating efficient facilities

- Increasing steam production through energy efficiency optimization

By integrating machine learning technology and AI, we offer digital smart fouling solutions that optimize the operation and maintenance of existing facilities and reduce unnecessary resource use, helping companies achieve their carbon neutrality goals.

(Smart Fouling Solution: Predicting the timing for fouling removal through monitoring and analysis of thermal conductivity trends based on various factors.)

Government support policies and regulatory environment

- Energy Use Rationalization Project Fund Support (Ministry of Trade, Industry and Energy/Korea Energy Agency): The government provides low-interest policy funds to encourage investment in energy-saving facilities in accordance with the "Energy Use Rationalization Act."

- Smart Factory Distribution and Expansion Project (Ministry of SMEs and Startups/Smart Manufacturing Innovation Promotion Team): This project supports the costs of establishing smart factories to promote manufacturing innovation among small and medium-sized enterprises.

- Strengthened Wastewater Discharge Regulations and Introduction of TOC: The strengthened industrial wastewater management system requires efficient monitoring for appropriate fouling removal and professional chemical cleaning.

Securing Operational Efficiency with Smart Fouling Solutions

Solve the double whammy of rising energy costs and environmental regulations, resulting from unnecessary energy and resource loss, faced by industries with Veolia's smart fouling solutions.

- Efficient operation of equipment by predicting effective fouling removal cycles: Optimizing operations through predictive maintenance.

- 20% annual cost savings: Reduce overall costs by reducing unnecessary resource and energy use.

- Achieving Carbon Neutrality Goals: Supporting our clients in achieving their ESG goals and ultimately achieving carbon neutrality.

Our experts collaborate with you remotely or from the Veolia Hubgrade Centers. Their expertise are augmented with digital services and AI to enhance, every day, your operations and to co-create innovation that fulfill your specific needs.

Hydrex® (the optimal water treatment chemical solution) for your company's extensive water treatment needs.

With Veolia’s continuous innovation and technological development, we can provide optimal solutions that meet customer expectations with Hydrx®. Through customized water treatment tailored to your facilities, fouling, corrosion, and scale formation can be prevented in advance.

A complete water treatment offer to support your productivity

- Protection of water treatment facilities from fouling, scale and corrosion

- Reduction of unnecessary operational shutdowns

- Ensured optimal productivity

- Energy savings

- Prevention and reduction of environmentally harmful factors

Hydrex, application-proven formulations to suit all your water treatment needs

- Boiler Treatment Solutions: Improve the efficiency of your boilers with our Series 1000 products, specially formulated to reduce scale formation and prevent corrosion.

- Cooling Water Treatment: Prevent scale deposits, corrosion, and microbial growth in your cooling systems with our Hydrex® 2000 and 7000 series solutions.

- Membrane System Optimization: Extend the lifespan of your membranes and minimize operational costs with our Series 4000, recognized for its exceptional performance.

- Industrial Wastewater Management: Enhance your wastewater treatment quality with our organic coagulants and heavy metal reduction technologies.